Ⅰ. Operating principle

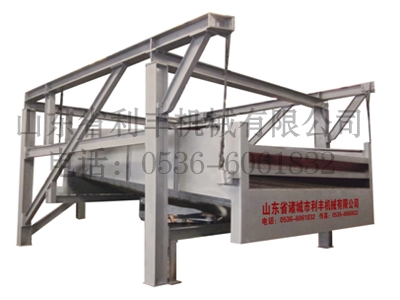

The chip sieve frame is hung to the four hanging seats of the bracket through four lifting ropes and inclines by a certain angle. The motor is driven by the V-belt to bring the shaft equipped with eccentric block to rotate and thus to rock. Therefore, when the materials enter the sieve frame from the feed inlet, they will scatter on the screen mesh along with the frame rocking. The materials are screened by the sieve plate with different size meshes to achieve sorting and continuous forward feeding. The materials of different specifications will be exported through different discharge ports.

Ⅱ. Main structure

1. Sieve frame: the sieve frame is welded by angle steel, steel plate and channel steel and equipped with sieve plate. The materials fall from the top and discharge from the designated position while the entire sieve frame is rocking.

2. Chip sieve drive: including the main shaft, motor, bearing, large and small pulley and eccentric block etc.

3. Chip sieve bracket: it consists of bracket and wire rope bridles. The sieve frame is suspended on the bracket through wire rope to allow the free rocking of the frame.

Chinese |

English |

Management

Other equipment

Other equipment

Ⅰ. Operating principle

The chip sieve frame is hung to the four hanging seats of the bracket through four lifting ropes and inclines by a certain angle. The motor is driven by the V-belt to bring the shaft equipped with eccentric block to rotate and thus to rock. Therefore, when the materials enter the sieve frame from the feed inlet, they will scatter on the screen mesh along with the frame rocking. The materials are screened by the sieve plate with different size meshes to achieve sorting and continuous forward feeding. The materials of different specifications will be exported through different discharge ports.

Ⅱ. Main structure

1. Sieve frame: the sieve frame is welded by angle steel, steel plate and channel steel and equipped with sieve plate. The materials fall from the top and discharge from the designated position while the entire sieve frame is rocking.

2. Chip sieve drive: including the main shaft, motor, bearing, large and small pulley and eccentric block etc.

3. Chip sieve bracket: it consists of bracket and wire rope bridles. The sieve frame is suspended on the bracket through wire rope to allow the free rocking of the frame.

The chip sieve frame is hung to the four hanging seats of the bracket through four lifting ropes and inclines by a certain angle. The motor is driven by the V-belt to bring the shaft equipped with eccentric block to rotate and thus to rock. Therefore, when the materials enter the sieve frame from the feed inlet, they will scatter on the screen mesh along with the frame rocking. The materials are screened by the sieve plate with different size meshes to achieve sorting and continuous forward feeding. The materials of different specifications will be exported through different discharge ports.

Ⅱ. Main structure

1. Sieve frame: the sieve frame is welded by angle steel, steel plate and channel steel and equipped with sieve plate. The materials fall from the top and discharge from the designated position while the entire sieve frame is rocking.

2. Chip sieve drive: including the main shaft, motor, bearing, large and small pulley and eccentric block etc.

3. Chip sieve bracket: it consists of bracket and wire rope bridles. The sieve frame is suspended on the bracket through wire rope to allow the free rocking of the frame.

Details

|

微信掃一掃